|

Propshield Industrial

features a special combination of

corrosion inhibitors and other chemicals which makes it powerful enough to endure hard labour day in

day out in the toughest of climes and in the foulest of waters.

Propshield Industrial bonds to the metal surface of a propeller in a simple 2 coat

application process. Once applied it ensures a surface is so

slippery that barnacles and hard growth are unable to securely

attach to its metal surface, oxidisation and electrolysis are

also nullified.

Unable to be dissolved in water the Propshield coating slowly

degenerates over time leaving a transparent bonded film retained

in the very pores of the metal ensuring the product remains

active for long periods of up to 18 months. Click

here

for details on product application.

Important: Propshield is no substitute for a good bonding

system, the product will work in conjunction with anodes to

eradicate electrolysis.

Propshield

Industrial also helps to eliminate or at least

significantly reduce the effects of electrolysis preventing propellers

dissolving into the water when shore power is connected. If a

propeller is green at the end of the season this is a sure sign that

the copper is leaching out of the bronze through galvanic action. This

weakens the metal and blades can sometimes break off and penetrate the

hull. At best the blade will loose efficiency and your fuel bills will

increase as your vessel's top/optimum cruising speed falls.

As with all antifouling products

Propshield

Industrial

performs at its best when a vessel is used regularly; the more a

vessel is used the more barnacles and hard growth are thrown off

from the force created by the rotating propeller and the lack of

adhesion caused by the Propshield coating.

Propshield

Industrial

will also perform well even if a vessel is inactive for long

periods of time. If a vessel has seen extended inactivity simply

take to sea and run at full speed for approximately 60 minutes

and most of the barnacles and hard growth that have adhered to

the props will be thrown off.

The

Bonding Process The

Bonding Process

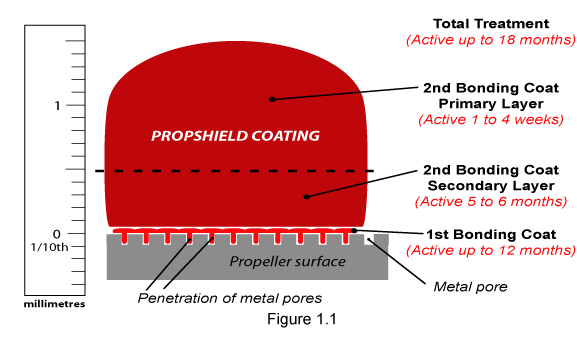

A macro

cross-section diagram of the product in action/application is shown in

Figure 1.1 on the right. As you can see the 1st coat of

Propshield bonds to the metal surface penetrating the pores of

the metal up to a tenth of a millimetre.

The 2nd bonding coat is

then applied on top of the first in a much thicker layer. This

second coat consists of two sub layers, primary and secondary.

2nd Bonding Coat

The

primary and thickest layer plays a critical part in protecting

the 1st bonding coat and secondary layer of the 2nd bonding coat

ensuring the products overall longevity.

This primary layer also

has the shortest active lifespan of just 1 to 4 weeks, this may

seem a short time however the primary layers job will have been

achieved, protection of the secondary sub layer of the 2nd

bonding coat and the 1st bonding coat.

After the Primary sub layer of

the 2nd bonding coat has finished its active life it will fall

away to reveal the much harder secondary sub layer of the 2nd

bonding coat, this transition from primary to secondary sub

layer is known as "shedding". Shedding can occur gradually over

a few weeks or all at once depending on various factors such as

vessel usage, local sea variables and ambient temperature during

application. Regardless of the time span the primary sub layer

will only "shed" itself once the secondary sub layer is hard

enough to begin its active role in protecting the propeller

surface. It is also important to note that any barnacles, hard

growth or weed growth that has attached itself to the propeller

during the initial 1 to 4 weeks will be ejected from the

propeller along with the primary sub layer during shedding.

Once the secondary

sub layer becomes active it will have achieved its optimum

solidity for protecting the 1st bonding coat and the metal of

the propeller beneath. During the lifespan of the secondary

layer, approximately 5 to 6 months, the surface will become

totally transparent resembling the 1st bonding coat during

application. It is prudent to point out at this stage that some

observers will take this transparency to mean that the product

has been washed away and the prop is no longer protected, this

couldn't be further from the truth as in fact the product has

only reached about a quarter of its active life.

1st Bonding Coat

The

1st bonding coat becomes active 5 to 7 months after a vessel has

been launched and has a lifespan of up to 12 months depending

on local fouling conditions and vessel usage. This final layer

of protection for the propeller is transparent from start to

finish and will act as the final defence against barnacles, hard

growth, oxidisation and electrolysis. Once the 1st bonding coat

has degenerated and finally left the pores of the metal a vessel

can be hauled out/dry docked for

Propshield

Industrial

to be reapplied.

If a vessel is not

able to be hauled out/dry docked once Propshield has run its

active life it is prudent to point out that at this time

propellers will be in excellent condition to continue active

duty for a lengthy period due to the protection Propshield has

provided for up to 18 months previously. For instance if a prop

usually needed to be cleaned after 1 year of service then after

Propshield had been used a prop would only need to be cleaned

after 2 and half years of service.

|